Direct-to-Garment printing, often called DTG printing, has become one of the most important technologies in modern custom apparel production. Merch companies, agencies, and apparel buyers rely on DTG printing when they need detailed graphics, small-batch production, or print-on-demand apparel without complicated setup.

If you manage merchandise orders for brands, schools, hospitals, or events, understanding how DTG shirt printing works helps you choose the right method, estimate costs correctly, and avoid production mistakes.

This guide explains everything about direct-to-garment printing, how DTG printers work, when to use DTG printing services, how DTG compares with other methods, and what merch partners should know before ordering.

What Is Direct-to-Garment Printing (DTG Printing)?

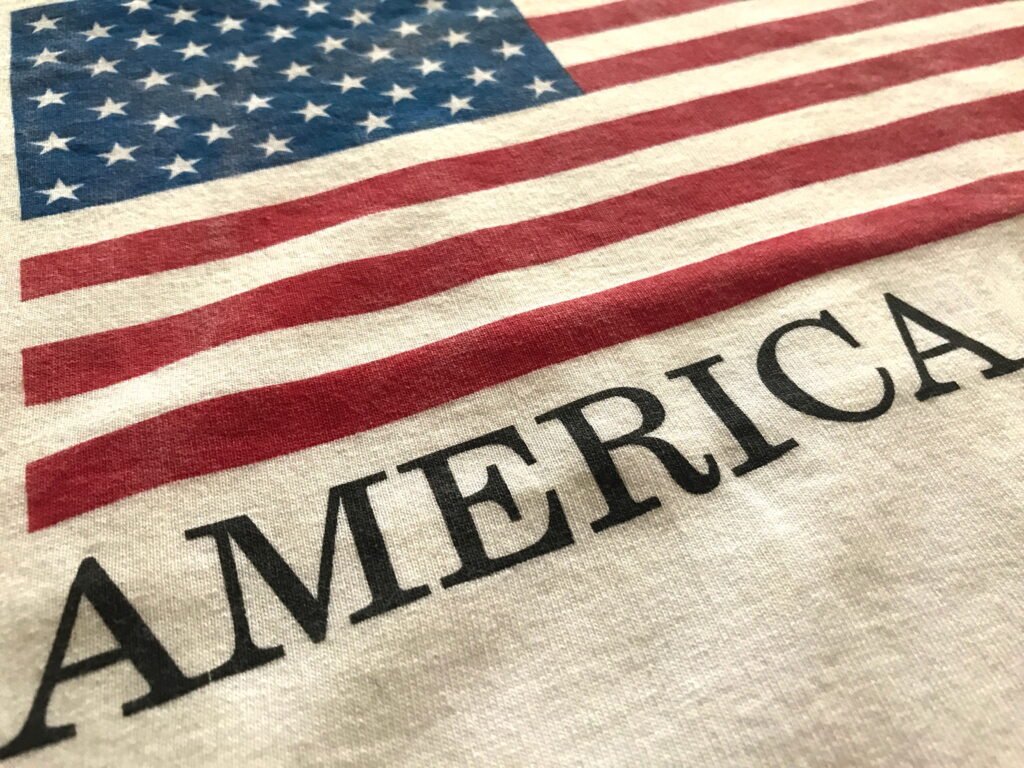

Direct-to-Garment printing is a digital printing process that prints designs directly onto fabric using specialized inkjet technology.

A DTG printer sprays water-based textile ink onto a garment, and heat curing bonds the ink into the fabric fibers. This creates detailed prints that feel softer than many transfer methods.

Unlike screen printing, which requires separate screens for each color, DTG printing can produce full-color images, gradients, and photo-quality artwork in one pass.

DTG printing t-shirts are widely used for brand merch, custom graphic tees, artist collections, and online apparel stores.

What is DTG Printing on Shirts?

DTG printing on shirts refers specifically to printing designs directly onto t-shirts, hoodies, or cotton garments using Direct-to-Garment technology.

Because the ink bonds with fibers instead of sitting thick on top, DTG printed shirts often feel smoother and lighter.

DTG shirt printing is commonly used when:

• Designs have many colors or gradients

• Orders are small or on-demand

• Each shirt needs personalization

• Brands are testing new designs

This flexibility makes DTG printing services popular with merch agencies and print-on-demand sellers.

What Is a DTG Printer?

A DTG printer is a specialized garment printer designed to print directly onto clothing instead of paper.

A typical DTG printer clothing system includes a printing unit, platen for holding garments, textile inks, pre-treatment equipment, and heat curing machines.

These printers allow one-off or small batch production without expensive setup. For merch partners managing multiple clients, this means faster design testing and less inventory risk.

How Direct-to-Garment Printing Works

The DTG printing process has several steps that ensure good color accuracy and durability.

First, artwork is prepared in high resolution. The garment is then pre-treated if necessary, especially for dark shirts. The DTG printer prints ink directly onto the fabric, and heat curing locks the ink into the fibers. Finally, garments are inspected before packing.

Because DTG printing skips screen setup, production can begin quickly once artwork is approved.

Best Fabrics for DTG Printing

Direct-to-garment printing works best on natural fabrics because ink bonds more easily with fibers.

The best results are usually seen on:

• 100% cotton

• Ring-spun cotton

• Combed cotton

• Cotton-rich blends

Polyester garments are less suitable because ink does not absorb as well. When planning merch orders, fabric choice is just as important as printing method.

When to Use DTG Printing Services

DTG printing services are the right choice when flexibility matters more than bulk pricing.

DTG printing t-shirts are ideal for small batch orders, highly detailed artwork, print-on-demand businesses, influencer merch, or personalized apparel.

Many merch partners use DTG printing to test new designs before moving to large screen-printed production runs.

DTG Printing vs Screen Printing

Understanding direct to garment printing vs screen printing is essential for choosing correctly.

Screen printing is usually better for large orders because setup costs are spread across many garments. It produces very durable prints and works well for bold designs.

Direct-to-garment printing is better for small orders or designs with many colors because it does not require screens. DTG printing shirt designs can include gradients and photo images that are difficult with screen printing.

The right method depends on quantity, design complexity, and budget.

DTG vs DTF Printing

Direct-to-garment printing prints directly onto fabric. DTF printing prints onto film first and then transfers onto the garment using heat.

DTF works on more fabrics such as polyester and blends, while DTG printing t-shirts usually produce softer results on cotton garments.

Some buyers mistakenly call DTF “direct to garment (DTF) print,” but they are different technologies with different use cases.

How Much Does DTG Printing Cost?

DTG printing costs depend on garment type, design size, ink usage, order quantity, and turnaround time.

Because there is little setup cost, DTG printing is affordable for small orders but more expensive per shirt than screen printing at large quantities.

For merch partners, the best approach is to compare printing methods based on total order size and expected demand.

How Durable Is DTG Printing?

DTG printing t-shirts can last dozens of washes when printed and cured properly.

Cold washing, gentle cycles, and avoiding high heat drying help preserve the print. While screen printing may last longer in heavy-use environments, DTG printing performs well for everyday apparel when cared for properly.

Advantages of Direct-to-Garment Printing

Handles complex artwork easily

Direct-to-Garment printing can reproduce detailed graphics, gradients, photos, and multi-color designs without needing separate screens. This makes DTG printing ideal for brand merchandise, artist designs, and custom graphics that would be expensive or difficult with screen printing.

Low minimum order quantity

DTG printing services can start from a single shirt or very small batch because there is no screen setup. Merch partners can test designs, produce samples, or run limited drops without committing to large inventory or high upfront costs.

Soft print feel on shirts

DTG printing on shirts allows ink to bond with fabric fibers, creating a smoother and more natural finish compared with thick transfer prints. This improves comfort and is important for customer satisfaction with branded apparel.

Fast production turnaround

Once artwork is approved, DTG printing t-shirts can be produced quickly since there are no screens to prepare. This helps merch agencies handle rush orders, small client jobs, and multiple projects efficiently.

Unlimited color printing without extra setup cost

Unlike screen printing, DTG printing allows full-color designs in one pass without additional charges for extra colors. This is especially useful for logos with gradients or detailed brand graphics.

Great for design testing and merch planning

Merch partners can use DTG printing to test new designs before placing bulk screen-printing orders. This reduces risk, improves client approval rates, and avoids large production mistakes.

Works well with print-on-demand workflows

DTG printing is commonly used in online merch stores because garments can be printed only when ordered. This reduces storage costs and unsold inventory.

Professional quality for small and medium orders

Even with low quantities, a DTG printer clothing setup can produce consistent, high-resolution prints that meet brand standards.

Flexible across different garment styles

DTG printing works on cotton t-shirts, hoodies, sweatshirts, and many cotton-blend garments, making it versatile for merch collections.

Limitations of DTG Printing

DTG printing is not ideal for every situation.

Per-unit cost is higher for large orders, polyester garments are less compatible, and durability depends on fabric and care.

For large event merchandise or uniforms, screen printing may be a better option.

Who Uses DTG Printing Most

DTG printing is widely used by merch companies, print-on-demand sellers, small clothing brands, artists, and corporate merch teams. It allows flexible production without holding large inventory.

For brokers managing multiple clients, DTG printing is often the safest way to test designs before scaling to bulk production.

FAQs About DTG Printing

Is direct to garment printing vs screen printing better for bulk orders?

Screen printing is usually better for bulk apparel because setup costs are spread across many shirts. Direct-to-garment printing is more suitable for small orders or complex designs with many colors.

What is direct to garment (DTF) print?

DTF printing prints designs onto film before transferring them onto garments. It is different from DTG printing, which prints directly onto fabric. DTF works on polyester and blended fabrics, while DTG works best on cotton.

Can DTG printing be used on hoodies?

Yes. DTG printing works well on cotton hoodies and sweatshirts, especially when surfaces are smooth.

How long does DTG printing take?

Small DTG printing t-shirt orders can often be completed in a few business days depending on production schedules.

Does DTG printing feel heavy on shirts?

No. Because ink bonds into the fabric fibers, DTG printing usually feels softer than many transfer printing methods.

Final Thoughts

Direct-to-garment printing has become essential in modern custom apparel production because it allows merch partners to produce small runs quickly, print detailed designs accurately, and test new ideas without large upfront investment.

Knowing when to use DTG printing services helps you balance cost, quality, and turnaround time for your clients.

If you’re deciding whether DTG printing is the right choice for your client’s next order, MLXL Pro can review artwork, recommend the best printing method, estimate production timelines, and help you choose fabrics that match your project goals. Work with MLXL Pro as your production partner and deliver custom apparel with confidence.

Start your project with MLXL Pro today

If you’re managing merchandise for brands, creators, or corporate clients, choosing between small batch and bulk printing shouldn’t be a guess, it should be a strategic decision. At MLXL Pro, we work as your production partner, helping you evaluate designs, quantities, timelines, and budgets so you can confidently guide your clients in the right direction.

Whether you need a test run, a large-scale rollout, or a fast-turnaround order, our team brings over 20 years of printing expertise, reliable workflows, and consistent quality to every project.

Let’s turn your client’s vision into professionally printed apparel without stress, delays, or costly mistakes.